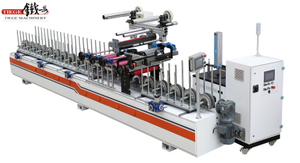

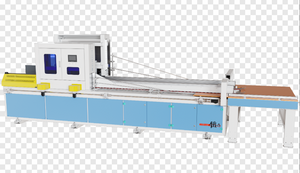

As a manufacturer specializing in architectural profile equipment, we designed the Two-Function Profile Wrapping Machine to meet factories that need both profile surface wrapping and flat lamination in one integrated line. This machine reduces equipment investment, saves floor space, and streamlines production while keeping industrial-grade stability.

1. Purpose of the Two-Function Profile Wrapping Machine

This two-function model is engineered for factories that need to process:

It supports both

(1) Profile wrapping: 3D and PVC decorative films, wood veneer, CPL, paper foil

(2) Flat lamination: high-gloss PET, PVC sheet, decorative laminate sheets

2. Key Advantages from a Manufacturer’s Perspective

(1) One Machine = Two Production Lines

A dual-function structure allows wrapping of irregular profiles and laminating flat boards without switching to another machine.

This reduces:

(2) Industrial-Grade Glue Application System

We equip the machine with our factory-standard glue system:

Slot coater for profile wrapping

Roller coater for flat lamination

Long-life steel roller with uniform glue distribution

Optional PUR hot melt adhesive system for high-strength bonding

Achieves higher bonding strength and avoids glue waste.

(3) Heavy-Duty Frame and Precision Conveying

Full-steel structure with vibration-resistant welding

Conveyor speed adjustable from 0–60 m/min

Servo-driven pressure rollers ensure stable pressure on both shaping molds and flat laminating surfaces

Suitable for 24-hour continuous production.

(4) Tooling & Mold Flexibility

We design and produce custom molds in-house:

Quick-change forming molds

Pressure wheel sets for different profiles

Adjustable vertical and horizontal guides

Shorter changeover time boosts efficiency for factories with multiple profile types.

(5) Smart Temperature & Tension Control

For consistent output, the machine is equipped with:

Film unwinding tension control system

Independent heating zones

Automatic temperature feedback

Film tracking alignment system

This ensures wrinkle-free and bubble-free lamination even for glossy or delicate films.

3. Machine Structure Overview

The machine includes the following modules:

Film Unwinding Unit

Pre-heating System

Glue Application System (Slot + Roller Combo)

Profile Wrapping Module

Flat Lamination Table

Pressure Roller Group

Cutting & Trimming Section

Control Cabinet (PLC Touchscreen)

All systems are integrated on a single frame to maintain alignment and reduce vibration.

4. Application Industries

Interior decoration manufacturing

PVC & aluminum profile factories

Furniture board manufacturers

Door frame producers

Wall panel & SPC trim factories

Construction moldings production

5. Why Customers Choose Our Factory

As a manufacturing factory, we control every detail:

In-house CNC machining of molds and roller parts

Independent electrical and assembly workshop

100% testing of every unit before shipment

OEM/ODM design available (support private label)

Exported to USA, Canada, Australia, Middle East, and Southeast Asia

Compared with single-function machines, our two-function model is more practical for factories with diverse product lines and small-batch customization needs.

6. Optional Upgrades (Highly Recommended for Export Lines)

PUR hot melt glue system

Auto film loading & splicing unit

Servo auto-lift pressure roller system

Dust removal & ionizing antistatic bar

Digital thickness measuring system