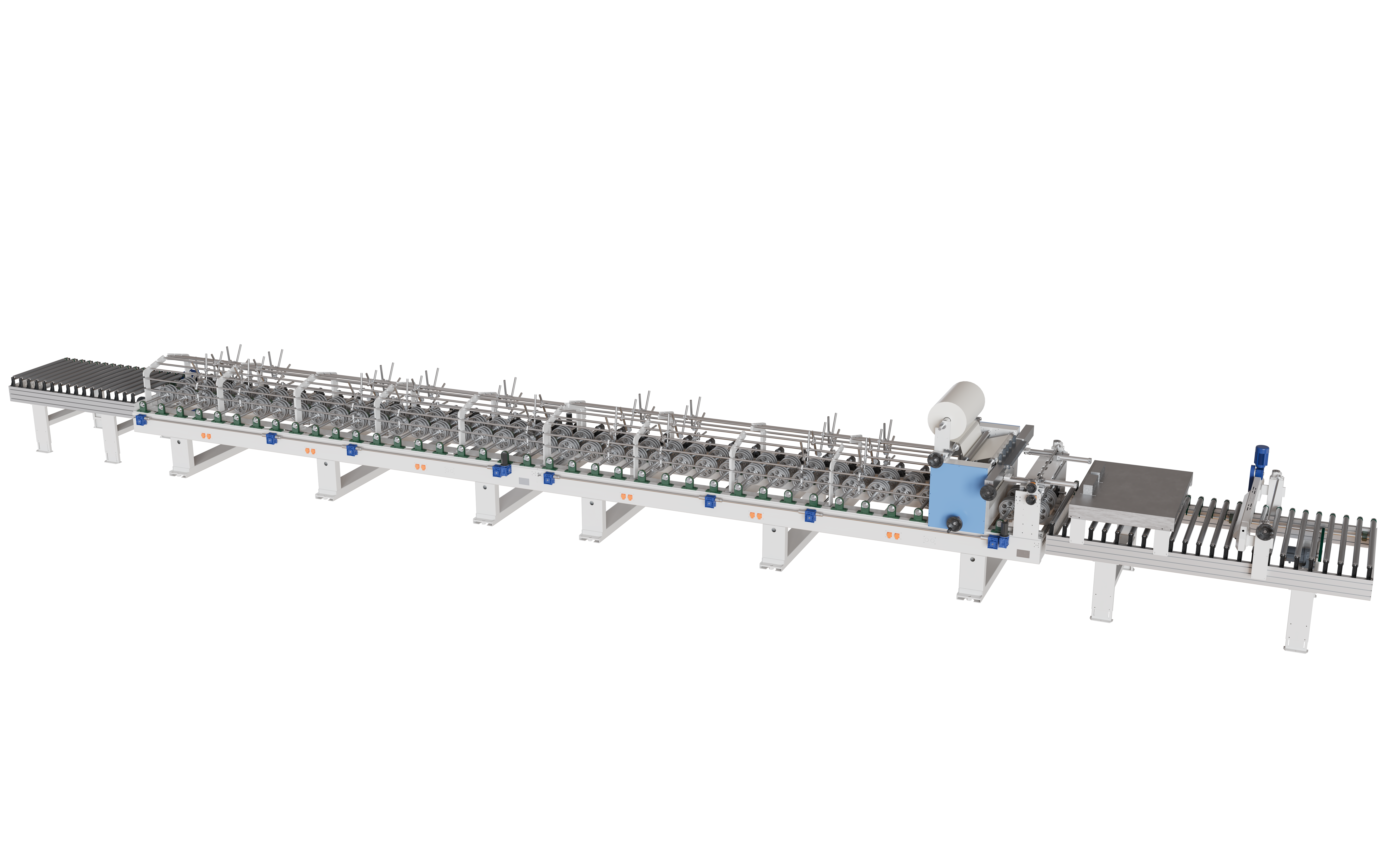

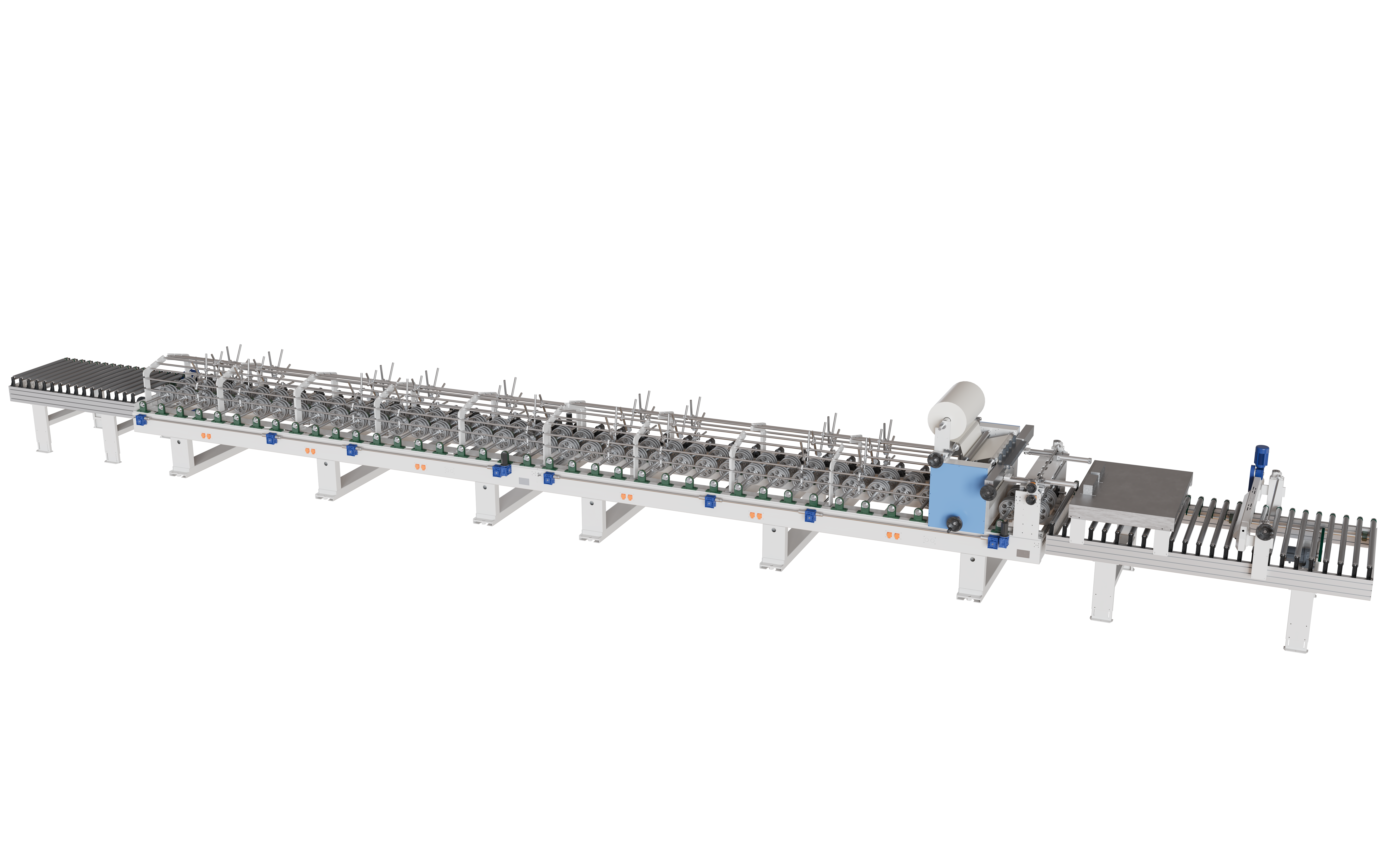

Factory-Engineered Equipment for Decorative Profile and Panel Finishing

As a manufacturer specializing in profile finishing equipment, we designed our Groove Wrapping and Lamination Machine to solve one common challenge in the furniture, interior decoration, and building materials industries: how to achieve a clean, durable, and precisely aligned decorative finish on grooved profiles and flat surfaces using a single integrated system.

This machine combines high-precision groove wrapping with consistent flat-surface lamination, giving factories a reliable solution for MDF, PVC, WPC, aluminum, and composite profiles.

1. Machine Purpose and Working Principle

Our machine is developed for manufacturers who need to finish:

Grooved profiles

Door and window frames

Skirting boards, wall panels, and trims

Mouldings with decorative channels

Flat panels requiring roll-film lamination

The system uses an adhesive-coating unit and controlled heating to activate the glue. The decorative film is then guided, stretched, wrapped, and precisely tucked into the groove with a dedicated forming blade. For flat surfaces, a lamination station applies uniform pressure for bubble-free adhesion.

2. Key Features & Technical Advantages

2.1 Precision Groove-Wrapping Structure

Servo-controlled blade for accurate film tucking into the groove

Adjustable groove width and depth ranges

Stable film tension control to avoid wrinkles

Quick-change forming tools for different profile designs

This ensures clean wrap lines and a tight fit even on complex grooves.

2.2 Integrated Surface Lamination Unit

Cold or hot-melt lamination depending on material

High-pressure rollers ensure even bonding

Suitable for PVC, PET, PP, HPL, and decorative paper films

Compatible with matt, gloss, embossed, and wood-grain surfaces

Factories can complete profile edge wrapping and panel surface lamination in one continuous process.

2.3 Industrial-Grade Adhesive System

PUR, EVA, or hot-melt adhesive options

Precision glue spreader with adjustable coating thickness

Rapid heating and temperature stabilization for 24/7 production

This reduces glue waste and improves bonding strength.

2.4 High-Efficiency Film Feeding & Cutting

Dual roll stands for fast material changeover

Automatic unwinding with tension control

Synchronized trimming units prevent film overflow

Designed for continuous long-run production.

2.5 Energy-Saving, Low-Maintenance Design

Modular heating zones reduce power consumption

Dust-removal unit improves lamination quality

Simple mechanical structure allows easy cleaning and maintenance

3. Supported Materials & Workpiece Sizes

Our machine can handle a wide range of substrates:

MDF / HDF / Particleboard

PVC, WPC, PS profiles

Aluminum and light-metal trims

Typical specifications (customizable):

Working width: 200–1300 mm

Profile height: 5–120 mm

Groove depth: 2–10 mm

Production speed: 10–40 m/min

We customize parameters according to customers' profile drawings and film specifications.

4. Applications in Manufacturing

The Groove Wrapping and Lamination Machine is commonly used in:

Furniture manufacturing (cabinet trims, decorative panels)

Interior finishing materials (wall panels, grooves, mouldings)

Door and frame production

Skirting and cornice factories

PVC/Aluminum profile finishing lines

It delivers a seamless appearance, consistent finish, and enhanced surface durability, which are essential for premium interior products.

5. Why Choose Our Groove Wrapping and Lamination Machine

From a factory viewpoint, the machine is built to deliver:

• Higher productivity

Full-automatic wrapping and lamination reduce labor and speed up delivery times.

• Clean edge performance

The groove-tucking system eliminates manual trimming and ensures precise alignment.

• Lower material waste

Consistent tension and optimized glue usage reduce both film and adhesive consumption.

• Stable long-run operation

Industrial components ensure reliability during continuous operation.

• Tailor-made solutions

We customize tooling, roller configurations, heating systems, and groove-forming blades according to your profile designs.

6. Optional Add-On Modules

To meet different production requirements, we offer:

Pre-heating IR lamps

PUR glue system

Profile-cleaning brush + dust collector

Automatic profile loader and unloader

Extra lamination stations

Edge-trimming knives

Customized forming dies for difficult grooves

7. Factory Support & Customization

As a manufacturing factory, we provide:

Technical drawings based on your profile samples

On-site installation & commissioning

Operator training

Long-term spare parts supply

OEM/ODM machine design for special profiles