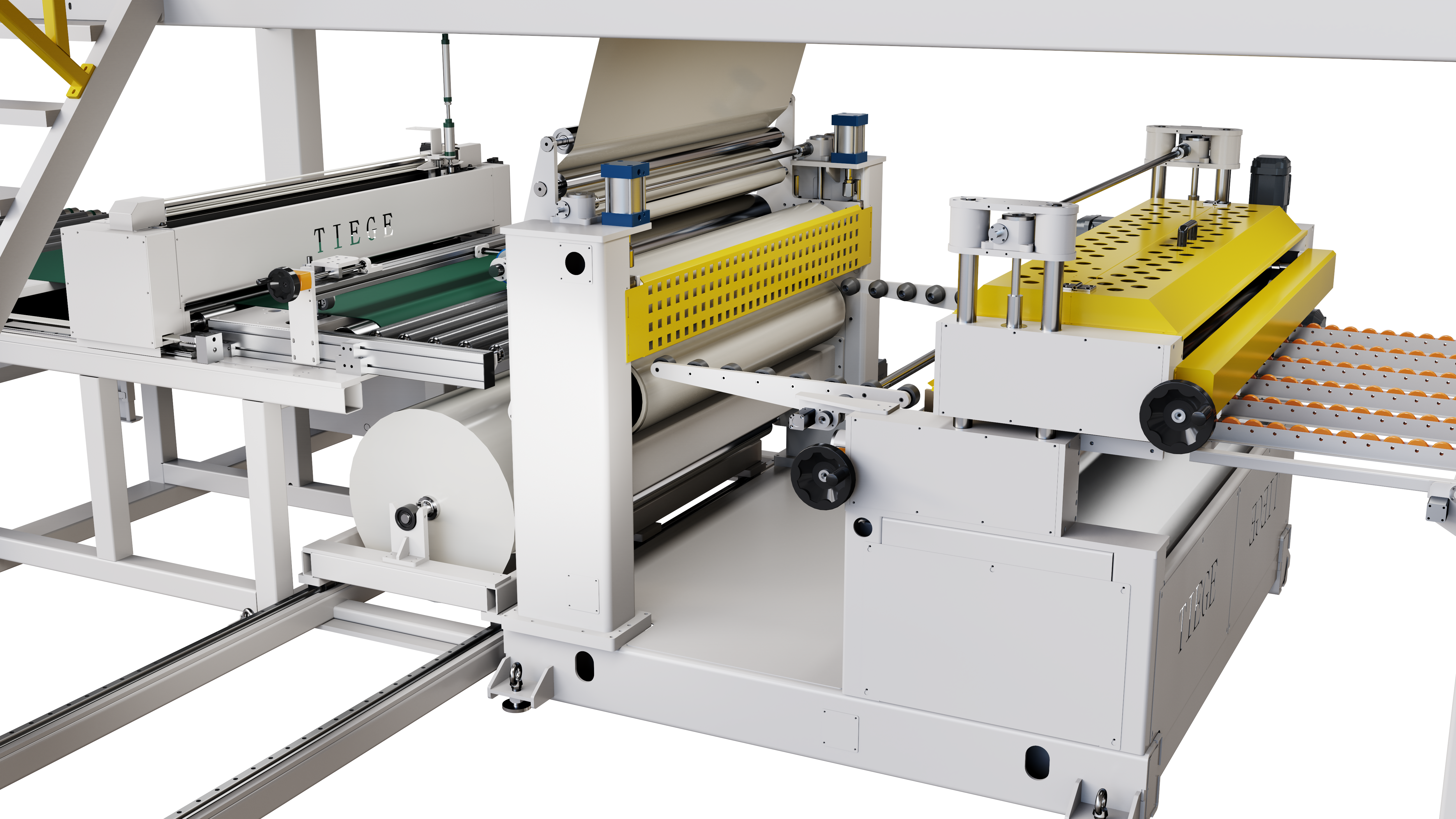

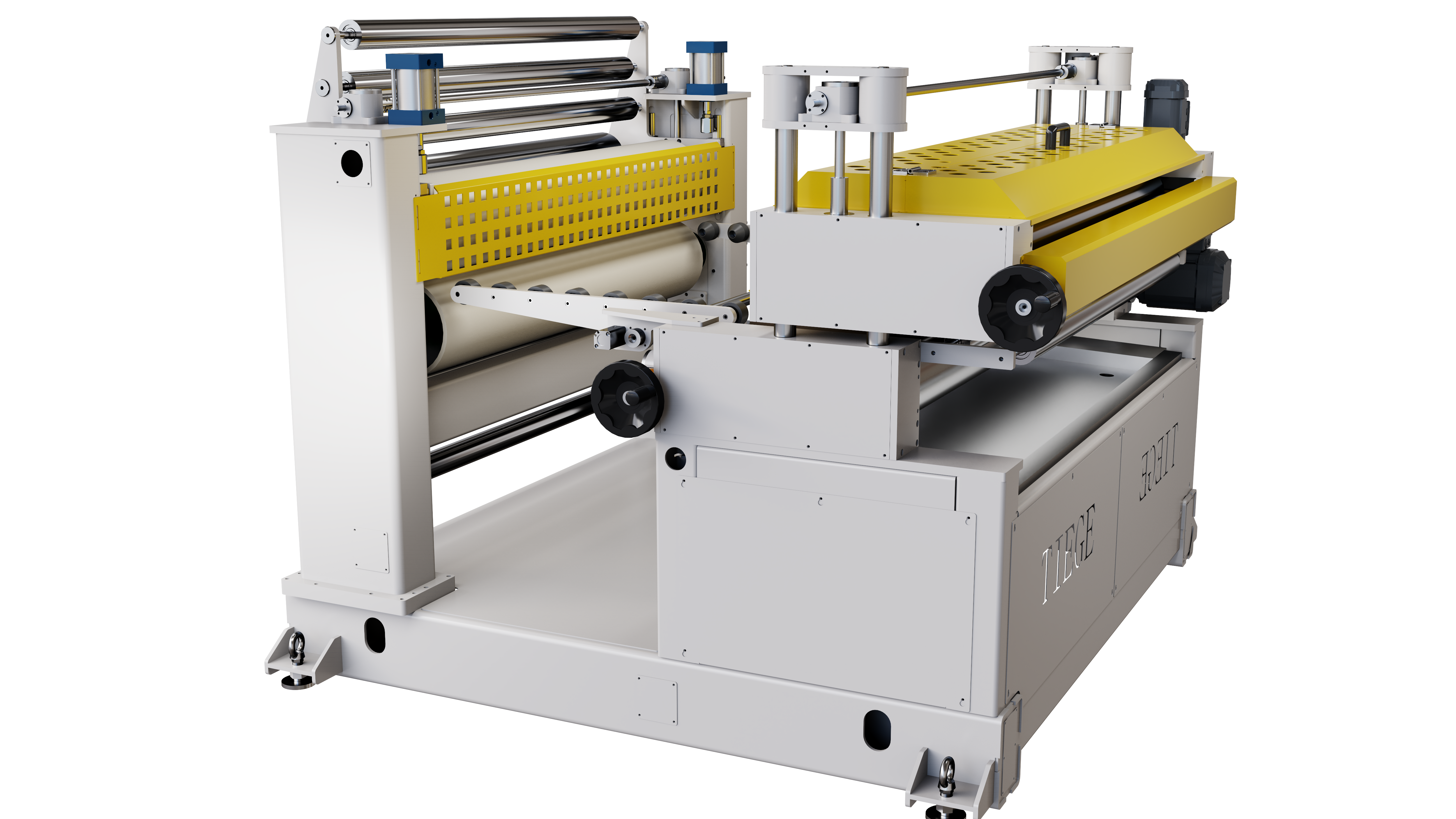

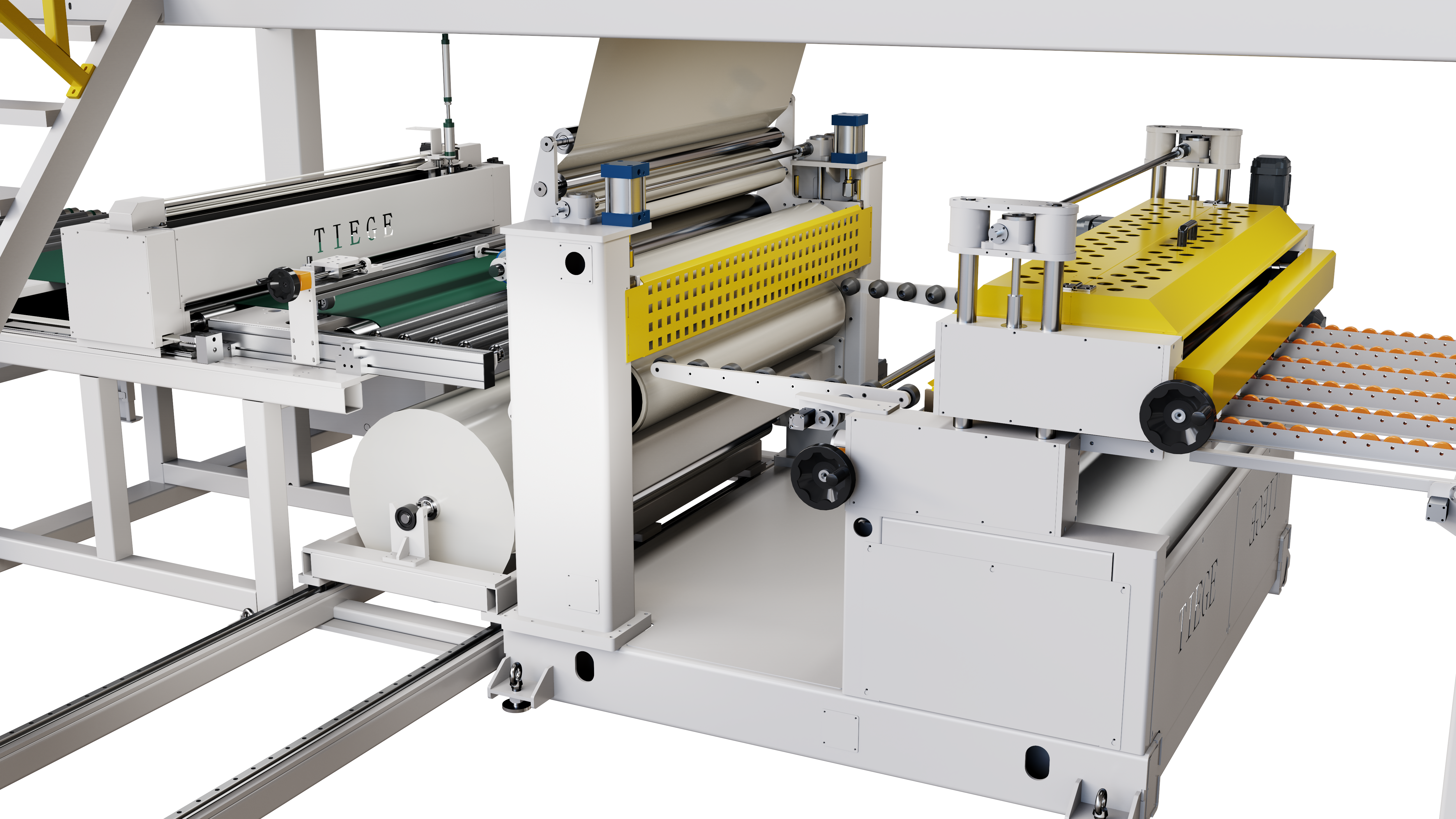

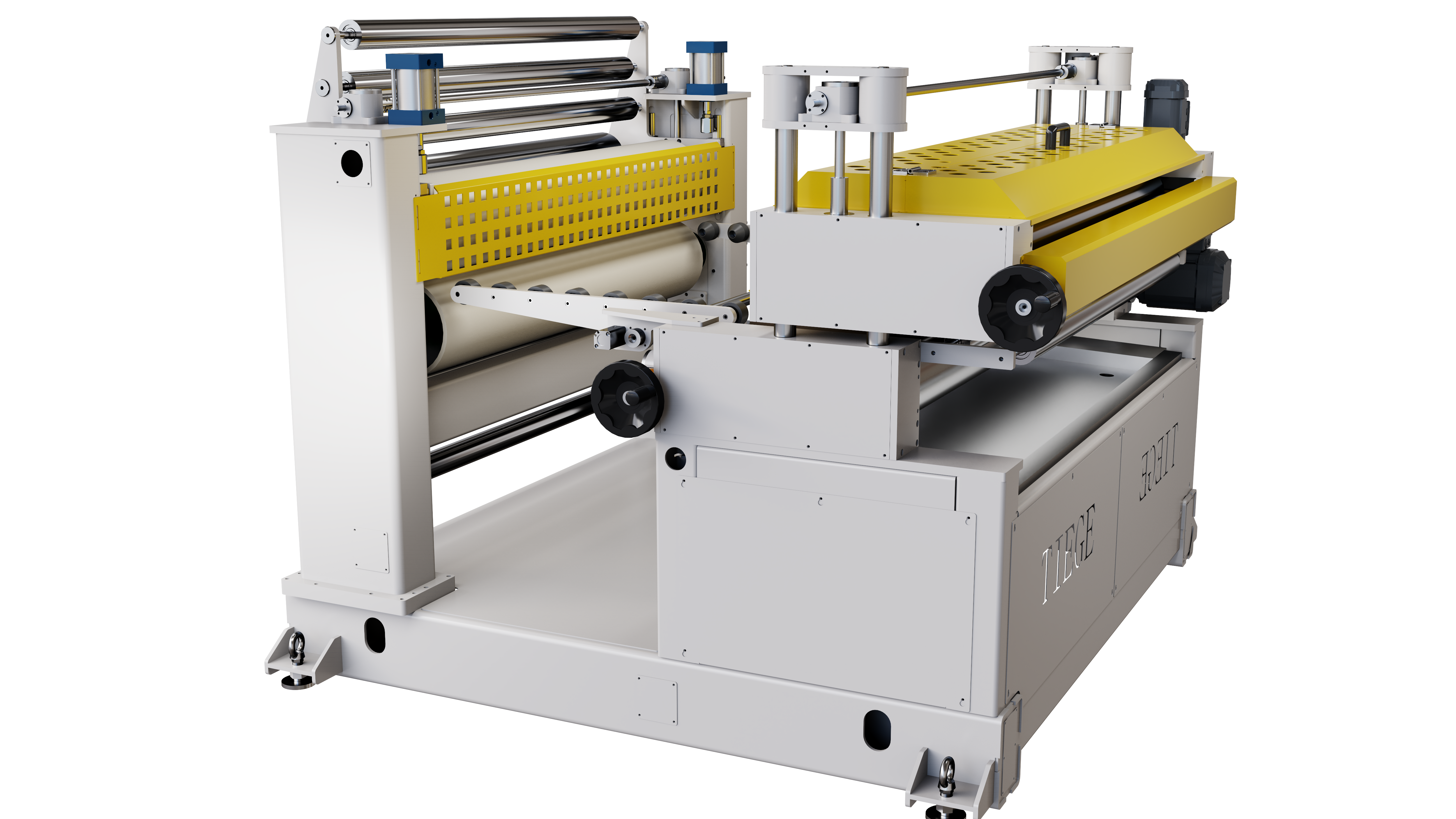

Introducing our Double Sided Lamination Machine, an essential piece of equipment for applying paper lamination on both sides of MDF (medium-density fiberboard) with white glue. To enhance production speed and product quality, this machine simultaneously applies lamination on both sides, providing a high-efficiency solution for businesses. Being a manufacturer ourselves, we take these things very seriously; consistency, durability and cost-effectiveness are a big part of mass production, and this machine helps to cover all these points.

5 Key Features and Benefits

1. Double-sided Lamination for Increased Productivity

This is a two-side laminating machine to laminate MDF boards. This configuration doubles the production speed and lowers the cycle times compared to a single-sided lamination system. This structure will allow you to achieve high-volume demand without sacrificing quality.

Allows Efficiency: This means cutting time and labor, improving overall production efficiency by eliminating multiple passes or extra handling.

2. Destined for White Glue and Paper

The machine uses white glue as the application, which works great for laminating paper to MDF. Recommendation If you are looking for a white type of glue which provides strong bonding and flexibility for most types of papers. This makes sure the paper is completely adhered with notable density and does not peel or lift over time.

Advantage: White glue imparts a smooth and impervious moist-proof surface to the laminated article.

3. Ensure accurate and repeatable lamination process

Advanced pressure control systems enable the glue to be applied evenly across the surface of MDF. This minimizes problems such as bubbling, wrinkling, or uneven lamination, which could compromise the product’s final appearance and durability.

Advantage: By ensuring a consistent quality and accuracy in the lamination process, wastage and the need for rework are reduced, ensuring industry standards of production are met.

4. Versatile and Scalable

It can work on many sizes of MDF boards and different paper thicknesses, based on the need.

Advantage: The unique flexibility in the system is the machine's suitability for both small and large production runs, enabling manufacturers to tailor the machine around their production requirements.

5. Automated and Easy to Operate

We used a lamination machine with a PLC (Programmable Logic Controller) system for automatic control of most processes (pressure and speed as well as adhesive application). This reduces the need for any manual intervention and lowers the chance of mistakes.

Advantage: Consistency of results and operation as well as low labor cost and negligible risk of human errors.

Technical Specifications

1. Maximum Board Size: Any size of MDF board wood can be worked by machine as per dimension required by customer made as per request.

2. Production Speed: The machine can operate up to optimal speeds to prevent downtimes, thereby ensuring production flow without interruptions.

3. Glue Application: Has high-tech glue spreading system for accurate, even white glue dispension.

4. Power Delivery: uses conventional industrial voltages and offer energy-efficient consumers, minimizing consumption costs.

5. Control System: PLC (Programmable Logic Controller)-controlled system which enables the user to operate and monitor the equipment, in addition the PLC can be linked to a touch-screen interfaces that can be used for online adjustment of set points.

Applications

Furniture Manufacturing: Suitable for MDF boards lamination used to create Furniture like Cabinets, Tables & Shelves.

Interior Decor: Suitable for lamination in decorative panels.

Custom Woodworking: You can use this for laminating MDF boards as part of custom wood projects, where decorative or protective wood layers are needed on both sides of the board.

Why Choose our Machine?

1. Simultaneous Double-Sided Laminate: This perfectly designed machine greatly reduces production time and labor costs by lumination through double-sided as well. It also reduces handling, streamlining the process and making it faster.

2. High-Quality Output: With an accurate gluing of the board and high-precision pressure system, all boards are laminated precisely and correctly, giving excellent adhesion and durability.

3. Reduced Material Waste: The precise application of adhesive or glue and even pressure ensures that less glue is wasted in the process.

4. Adjustable and Flexible: adjustable to suit different fermentation sizes, this machinery is equally ideal for everything from litre-batch production to full scale generation which makes it an incredibly useful machine for your business.

Conclusion

At our Double Sided Lamination Machine manufacturing plant, we build machines that are tailor-fitted for high production rates, making this superfast production machine ideal for businesses with production in mind. It is well-suited for a range of industries that need dependable, high-speed lamination, thanks to its efficiency, versatility and precision. Even if you wish to step into the automatic injection product types, this machine is an investment that can bring productivity as well as product quality improvements.