As the world of manufacturing continues to evolve, there has been a noticeable shift towards the use of advanced technologies and automated systems in almost all industries. The same is true for door frame production, where innovative approaches and technologies are constantly being developed to improve efficiency, reduce costs, and increase quality. A significant development in this field is the introduction of the Door Frame PUR Wrapping Machine, which is revolutionizing door frame production with its advanced PUR technology. In this article, we will explore the future of door frame production and the impact of the Door Frame PUR Wrapping Machine.

Background on Door Frame Production

Door frame production is an essential component of the construction industry. Essentially, door frames provide the necessary structure and support for doors, ensuring stability and functionality. Door frames are usually made of wood or metal and are produced in a variety of types and sizes to suit different applications. Over the years, door frame production has undergone several changes, from traditional manufacturing methods to more modern and automated approaches. In the past, door frames were usually crafted by hand, requiring a substantial amount of time and labor. However, with the advent of new technologies and manufacturing techniques, the process of door frame production has become more efficient and cost-effective.

Traditional Manufacturing Methods versus Automated Systems

One of the most significant changes in door frame production over the years has been the introduction of automated systems. Automated systems have completely transformed the manufacturing process by reducing labor input while increasing efficiency, productivity, and output rates. Unlike traditional manufacturing methods, automated systems rely on advanced technologies and computer-controlled machinery to perform operations. By utilizing these technologies, automated systems can minimize the occurrence of human errors, improve consistency, and increase precision in door frame production. In addition, automated systems can operate without interruptions, 24 hours a day, seven days a week, thus improving overall productivity and reducing downtime.

The Benefits of Using the Door Frame PUR Wrapping Machine

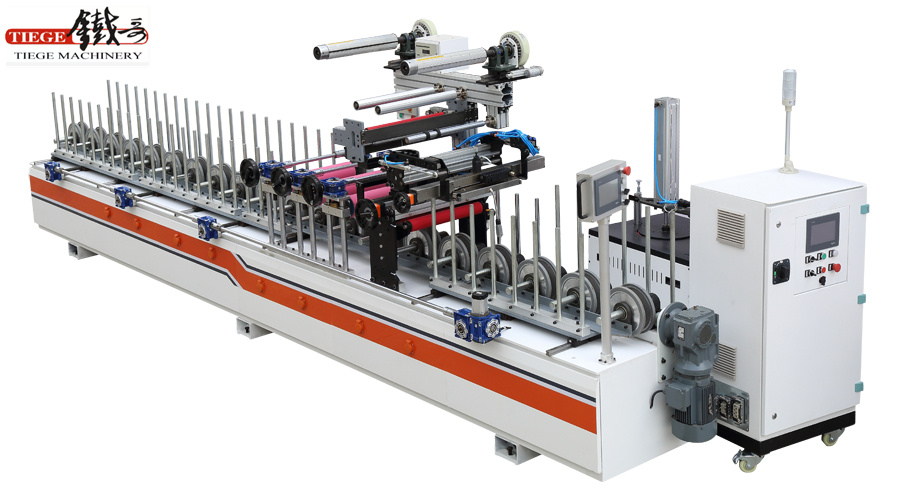

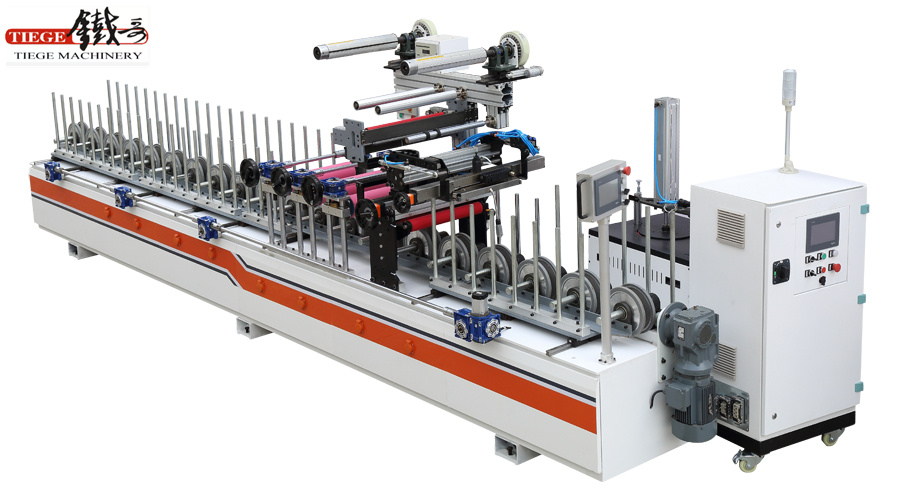

The Door Frame PUR Wrapping Machine is a revolutionary system that has taken door frame production to a new level. It is a highly innovative and advanced machine designed for the production of wrapped door frames. The machine utilizes Polyurethane Reactive (PUR) technology to produce high-quality, durable, and lightweight door frames. PUR technology is an adhesive used in bonding various materials together, and it has been widely used in several industries, including furniture, automotive, and construction. It offers several benefits over traditional adhesive technologies, such as enhanced adhesion, increased durability, weather resistance, and improved chemical resistance.

The Door Frame PUR Wrapping Machine combines the benefits of PUR technology with the advantages of automated systems. By incorporating these two technologies, the machine can produce wrapped door frames of various sizes and types, with a high degree of precision and accuracy. The wrapping process is fully automated, ensuring consistent wrapping quality, and reducing the chances of human errors. Additionally, the machine can operate at high speeds, achieving an output rate of up to 50 door frames per hour, thus improving overall productivity.

Efficiency and Automation

The Door Frame PUR Wrapping Machine is an excellent example of how advanced technologies can improve efficiency and automation in door frame production. The machine's fully automated wrapping process eliminates the need for manual labor, significantly reducing the time required to produce wrapped door frames. Additionally, the machine's high-speed performance enables it to complete multiple wrapping tasks within a shorter timeframe, thus increasing overall efficiency. Moreover, the machine features an intuitive control panel that allows operators to monitor and control the wrapping process, improving overall operational efficiency.

Quality

The quality of door frames produced using the Door Frame PUR Wrapping Machine is exceptional. The machine's use of advanced PUR technology ensures that wrapped door frames are durable, lightweight, and resistant to weather and chemical exposure. The wrapping process also ensures a tight and consistent seal around the door frame, preventing any air or water leakage. Additionally, the machine's automated wrapping process ensures consistency in wrapping quality, reducing the chances of defects or imperfections.

Flexibility

The Door Frame PUR Wrapping Machine is a highly versatile machine that can produce wrapped door frames of various sizes and types. The machine can accommodate door frames with different thicknesses, widths, and lengths, making it an ideal solution for customizable door frame production. Additionally, the machine can produce wrapped door frames with different finishes, colors, and designs, enabling manufacturers to meet the unique needs and preferences of their customers.

Environmentally Friendly

The Door Frame PUR Wrapping Machine is an environmentally friendly solution for door frame production. The machine's use of PUR technology reduces the amount of adhesive required for wrapping, thus minimizing waste. Additionally, the machine's high-speed performance and reduced labor requirements help reduce energy consumption, further minimizing its carbon footprint. Furthermore, the machine's output is consistent and of high quality, reducing the likelihood of wasted materials.

Conclusion

The Door Frame PUR Wrapping Machine is a revolutionary solution that is transforming door frame production. Its use of advanced PUR technology, coupled with its automated operation, ensures high-quality wrapped door frames that are durable, lightweight, and resistant to environmental factors. The machine's high-speed performance, versatility, and environmentally friendly design make it an ideal solution for door frame manufacturers looking to improve efficiency, quality, and productivity. As the future of door frame production continues to evolve, the Door Frame PUR Wrapping Machine is poised to play a significant role in shaping the industry and transforming the way manufacturers approach door frame production.