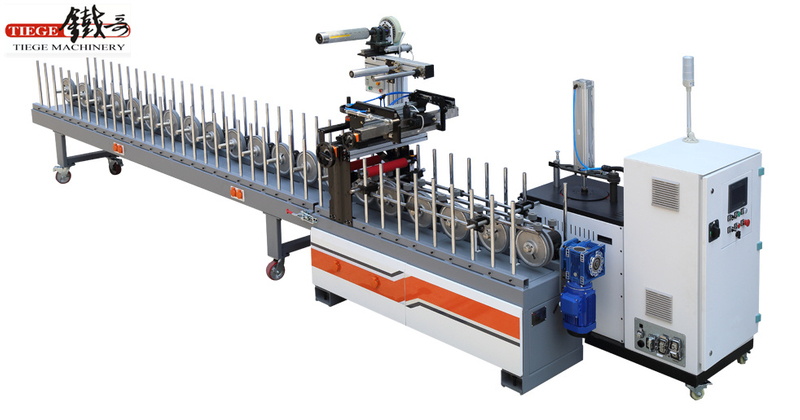

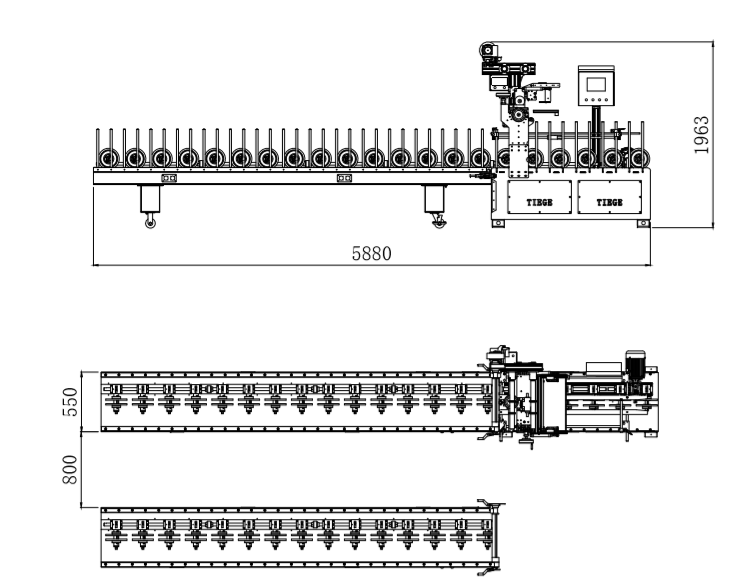

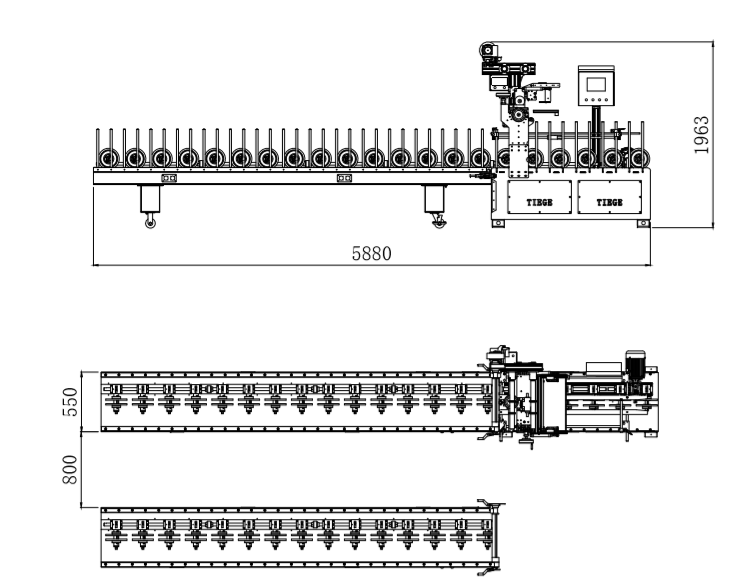

Length Of Machine Is 5.8 Meter

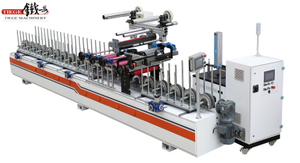

Model:FMF-300PURF1

Specification

Max.Process Thickness | 80mm | Max.film Covering Width | 300mm |

Process Length | 600mm—indefinite length | Feeding Speed | 0-25m/min(According to the actual production status) |

Power Of Material Delivery Motor | 2.2kw | Max.diameter of Roll Cover Material | 500mm |

Heating Power | 16KW | Weight | 3000kg |

Overall Dimensions | 5800 x 1000 x 1800mm |

(Wrapping PVC,paper ,high glossy ,leather, CPL, aluminum foil on MDF board , particle board, wooden line ,aluminum ,wood plastic and so on .)

1) With a 5 gallon PUR hot melt glue system.

2) Glue cutter , can divide and close in middle.

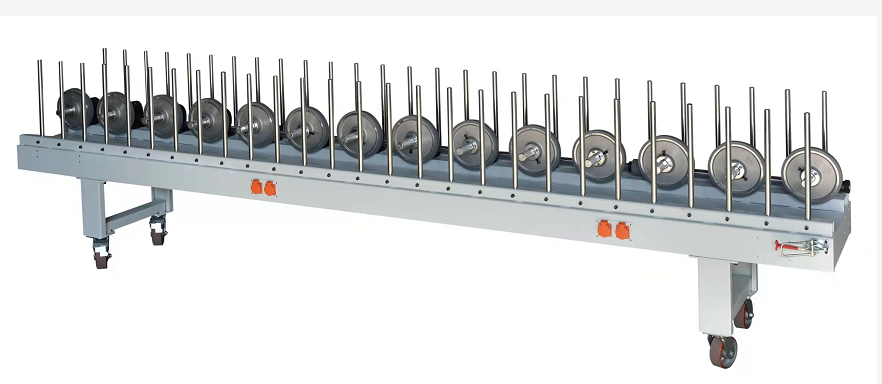

3) Stud and quick change frame can choose one of them .

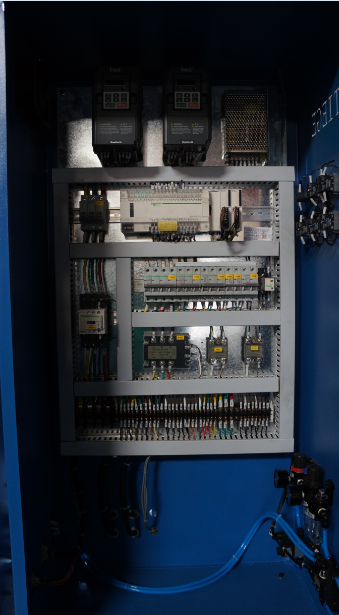

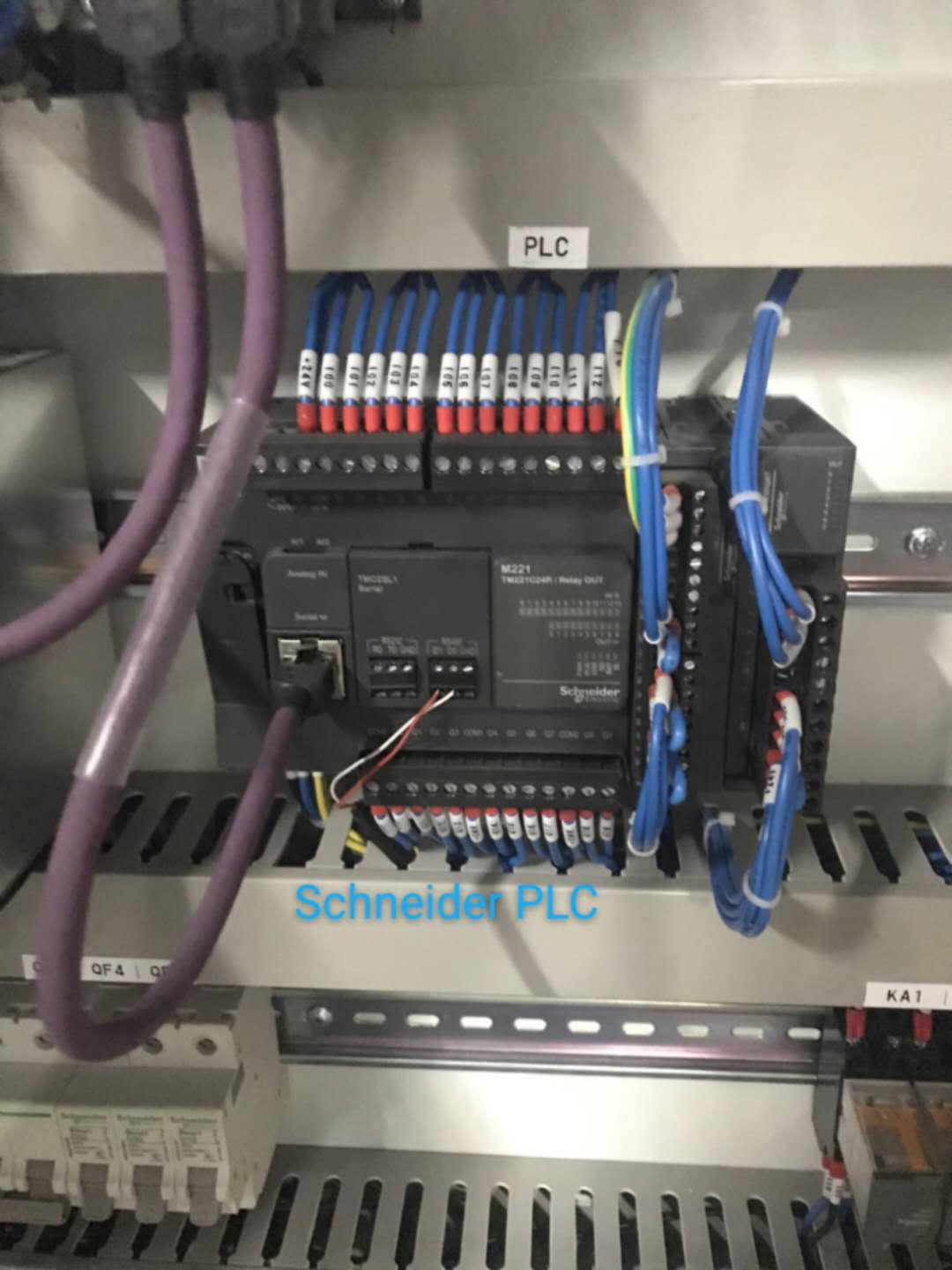

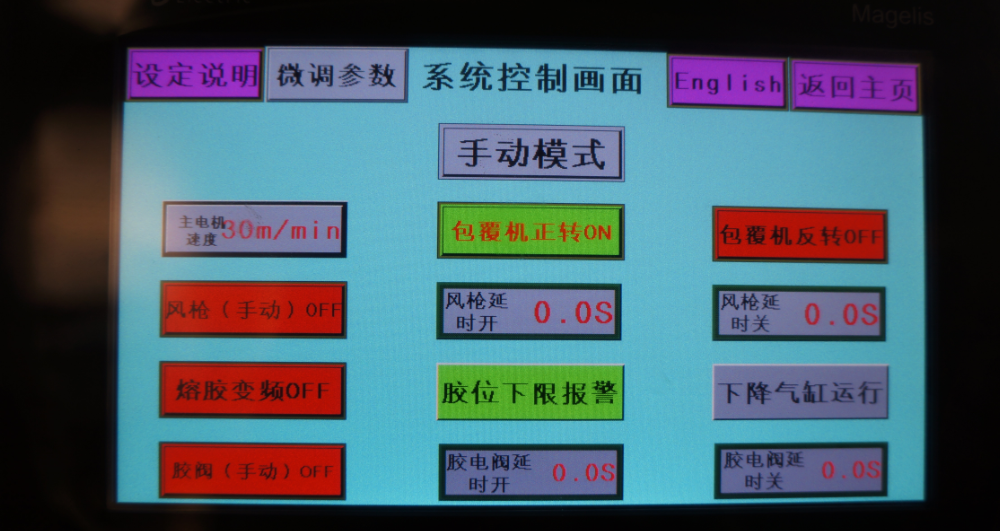

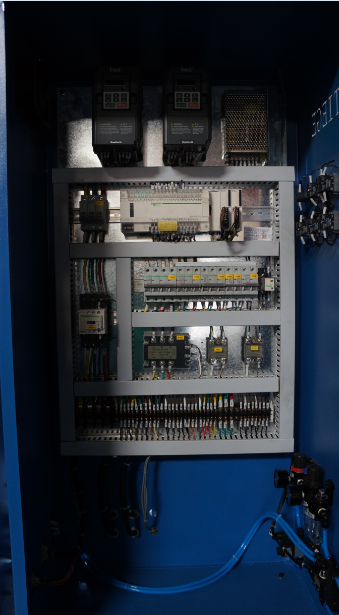

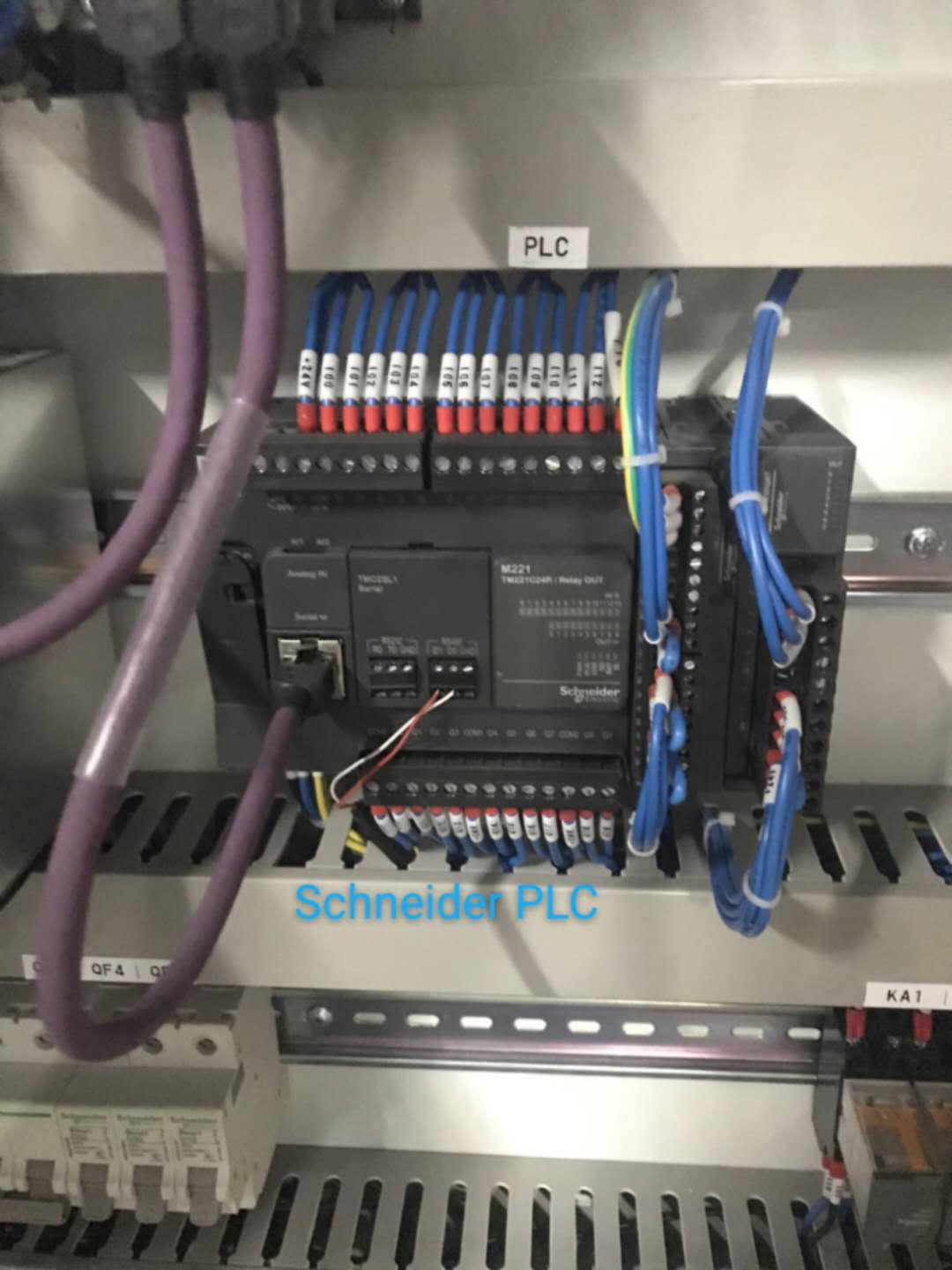

4) Electric brand,PLC: France brand, Schneider

Pneumatic brand: Taiwan Airtac .

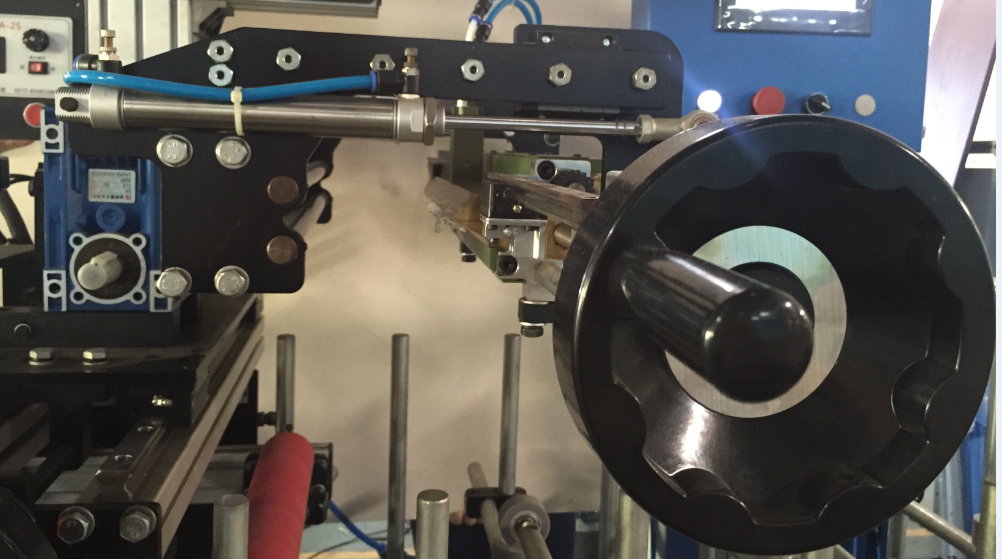

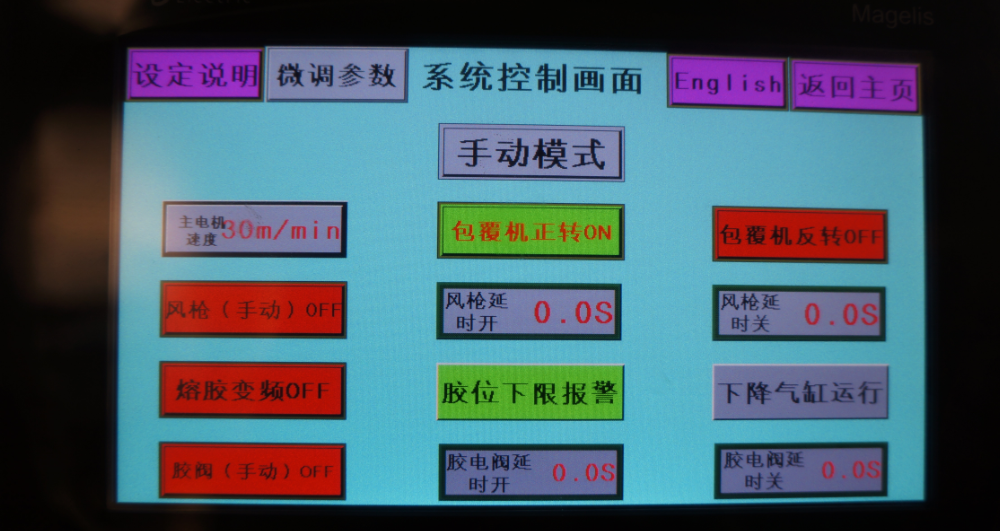

Mechanical appearance (To design for real now):Touch screen display ,PLC system control.

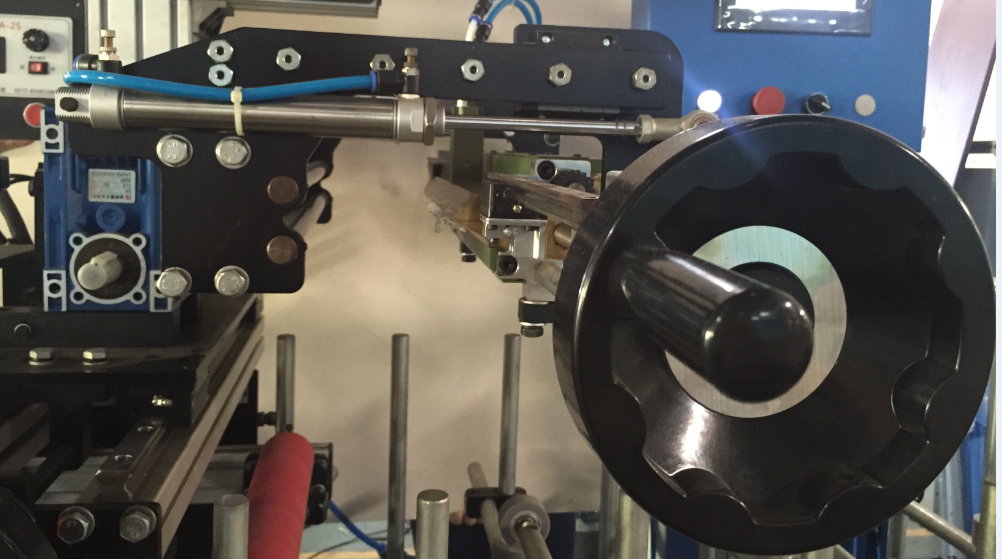

1. Sealing glue cutter ,spread glue on the film ,can control the width of spread glue better, can wrap any profile , it’s easy adjust width , just need to divide from middle to both sides, after finish working need to close and sealing by scotch tape .

2. 5 gallon PUR hot melt glue system , this machine use PUR glue ,after glue melting through high temperature arrived to glue cutter and spread , melting speed according to the production speed of machine to automatic adjust glue output, before the glue through the glue cutter , it need to through the filter twice ,so there won’t be particles and make glue line when spread glue .

Images

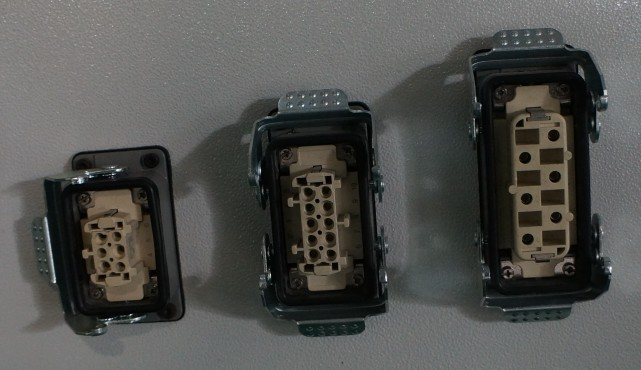

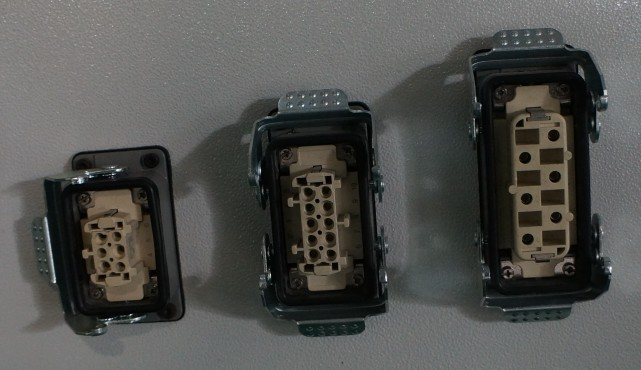

3. The hot melt glue system and machine wire butt joint by adopt aviation socket ,it’s easy operate .

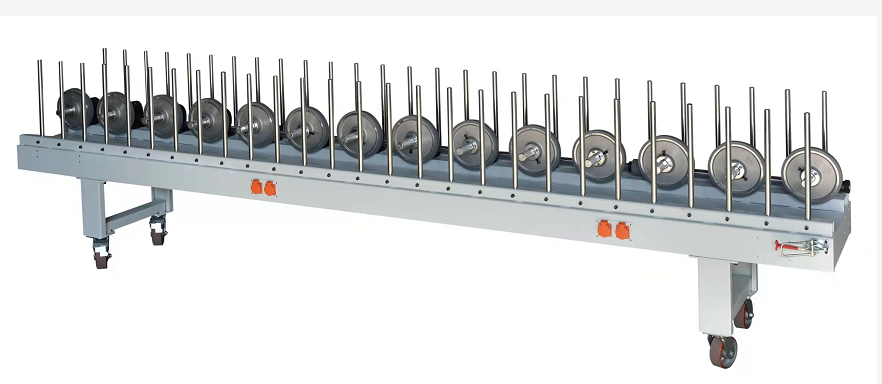

4. It is have a activity machine fram by each profiles,save time to install rollers,the profiles muston an qual footing,the max.wrapping widths is 420mm.

5. Linear profile wrapping picture, according to different profile make different adjust , profile must be parallel between line and line , the max width of cover film is 300mm.

6. Production sample.

The PLC in both Chinese and English