| Availability: | |

|---|---|

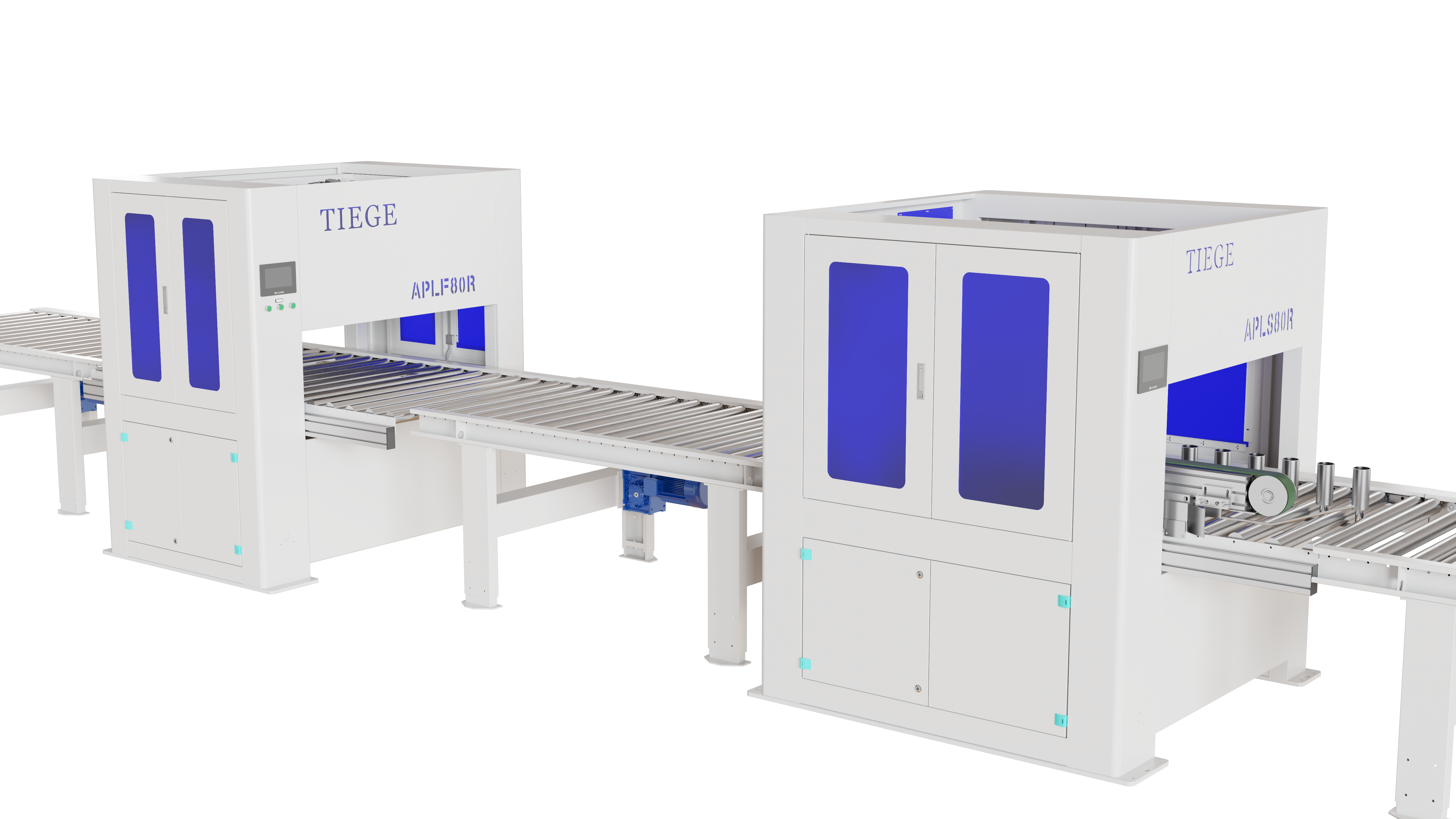

Product Description

A semi-automatic paper box sealing machine is an indispensable machine in industries that need high-volume box sealing with minimal immediate labor. In the example above, the machines use glue to coat the paperboard boxes, allowing for strong, reliable seals that lock the box closed for storage, shipping, and retail packs. They can provide a solution for companies who require a combination of manual and automated processes.

Semi-automatic machines require operators to place boxes on a conveyor by hand, but they are made for sealing the package. This alleviates operator fatigue, while still allowing for flexibility and control. Sealing Average Cycle Time is approximately 5-10 seconds per box, depending on size and material.

Semi-automatic machines can be simply adjusted based on the size of box. Typical box dimensions are 12"x12"x12" to 24"x24"x24", and the machines will normally seal from 100 to 800 boxes per hour (depending on speed setting and operators).

Built with heavy-duty or light-weight parts for the right kind of materials like cardboard boxes, kraft paper boxes, etc. Certain machines can load weights up to 50 kg per box, making it useful for products in types of industries such as electronics, food, or manufacturing.

It's the mechanism that ensures the tape is applied with speed and precision, while an automatic tension control helps to avoid slack. This minimizes waste and rework, thereby enhancing packaging quality.

Considering their compact design, semi-automatic paper box sealing machines are perfect for any company with a space constrain. They are very easy to operate, require very little training, and machines can usually be tweaked for different types of seal patterns (top, bottom, or both).

Packaging can be high volume • Speed and accuracy is critical in e-commerce In this type of work, a semi-automatic sealing machine can seal 500-800 boxes per day, which is ideal for fulfilment centres operating on a fast-paced scale. It is designed to seal small and large boxes containing products, including books, clothing and consumer electronics.

Semi-automatic sealing machines work for securing paperboard cartons or boxes for food packaging, particularly for bulk or bulk shipping to retailers. Machines in this sector seal up to 800 boxes per hour and are designed for boxes with weight up to 20 kg — common in beverage and canned goods packaging.

Semi-automatic machines seal boxes containing fragile or expensive items for industries such as electronics, where protective packaging is critical. Ideal for heavier or bulkier products, these machines can seal boxes up to 36 inches long.

These machines are used for high-volume sealing in warehouses and distribution centers, particularly for packaging requiring visual consistency. Semi-automatic machines can work on assembly lines, sealing boxes in rapid succession before they go out for delivery. These systems make it possible to seal 800 packages a day, increasing throughput in shipping operations.

Conclusion:

The semi-automatic paper box sealing machine is the perfect combination between manual control and fully automated machine. It optimizes productivity, reduces labor costs, and provides uniform, high-quality seals in many industries. Able to operate at speeds of 800 boxes/hr and process boxes as small as 12"x12"x12" to as large as 24"x24"x24" in dimension, these machines are efficient and economical for medium to large-scale requirements.